Our aim is to raise the bar in terms of quality and life span of our products which in turn will give better value for money, and less down time in mining operations globally. We have the ability to offer custom made compounds and products that can be tweaked to match each individual processing plant, thus streamlining the surface protection of the steel work and increasing the lifespan of those items which our rubber is applied to.

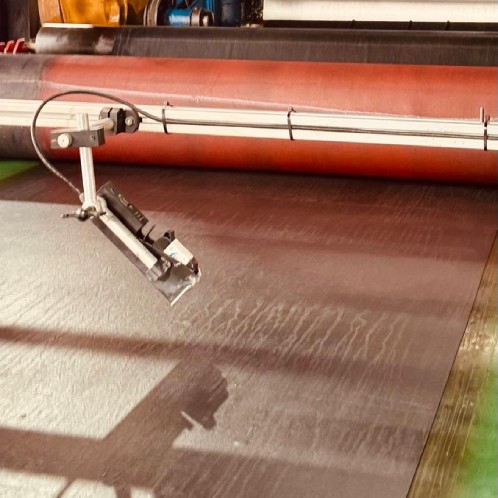

Our current portfolio includes a low abrasion loss 40 shore Natural Rubber Red & Black designed to extend the life of pipes and tanks in a slurry application, a high quality 60 shore Natural Rubber Red & Black great for tanks and chutes which have larger particle sizes and with a better impact resistance, a 50 Shore Bromobutyl which necessitate superior resistance to mineral acids, saltwater, rainwater, acidic or alkaline solutions, and a 60 Shore Nitrile that exhibits excellent resistance to oils, fuels, and hydrocarbons, making it suitable for applications involving prolonged exposure to such substances.

We also have a premium range of rubber sheeting and can offer custom made solutions to suit the particular process and material that is running through the mining plant.

Engineered for the toughest mining environments, our rubber products deliver unmatched durability and performance. From heavy-duty seals and gaskets to advanced moulded components, we provide solutions that stand up to extreme abrasion, impact, and chemical exposure. Our Ceramic Embedded Wear Pads offer superior wear resistance, extending equipment life and reducing maintenance downtime. Trusted by mining professionals, our products are built to keep your operations running longer, safer, and more efficiently.

Our mining process is built on precision, safety, and efficiency — ensuring reliable material handling and reduced downtime in even the most demanding environments. Supporting this is our dedicated Rubber R&D Department, where innovation meets performance. Through continuous research and material testing, we develop advanced rubber compounds tailored for extreme mining conditions. From concept to application, our team drives solutions that enhance durability, reduce wear, and push the boundaries of what's possible in mining technology.

Whether it be fabricating, lining and coating replacement parts for any area of the mines, or full project fabrication, management and quality control, we are able to call upon our various partners to complete small and large projects.

We can advise on correct pressure ratings of pipes and fittings, rubber type and thickness to different lifespans, external or internal coating specifications and other items such as pumps, valves and spares needed in the mining process. We also offer other lining capabilities such as ceramic & silicon carbide linings, Polyurethane and HDPE linings, and Straight supply of HDPE & PVC piping and fittings.